Learning Outcomes

i. Delve into the captivating realm of metal extraction, exploring the methods employed to recover valuable metals from their natural sources – ores.

ii. Identify the fundamental principles underlying metal extraction, including physical separation, chemical reduction, and refining processes.

iii. Understand the concept of gangue minerals and the importance of their removal from ores during processing.

iv. Recognize the significance of metal extraction in various industries and modern technologies.

v. Appreciate the environmental considerations associated with metal extraction processes and the efforts to minimize their impact.

Introduction

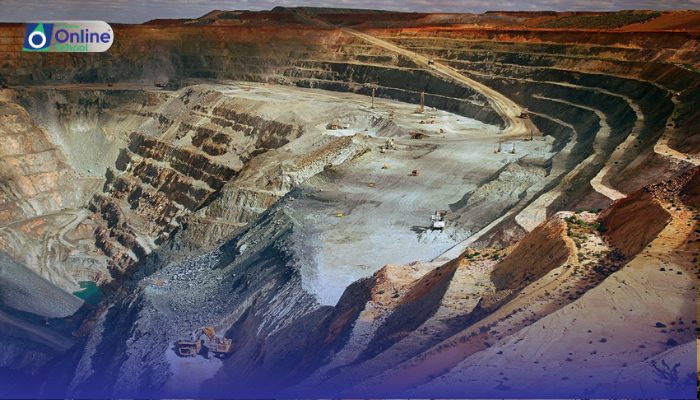

In the captivating world of chemistry, where elements dance with transformations, metal extraction emerges as a crucial process that unlocks the potential of valuable metals hidden within their natural repositories – ores. These diverse and often complex materials, composed of various minerals, hold the key to shaping our modern world, providing the building blocks for infrastructure, electronics, and countless other applications. This lesson will embark on a journey into the intricacies of metal extraction, illuminating the methods employed to recover these precious resources.

i. Physical Separation: A Tale of Sifting and Grinding

Physical separation techniques play a vital role in the initial stages of metal extraction, particularly for ores containing metals with distinct physical properties. These techniques include:

Crushing and grinding: Ores are mechanically crushed and ground into smaller particles to facilitate further processing.

Froth flotation: This technique utilizes the difference in surface properties between metal-bearing minerals and gangue minerals. Metal-bearing minerals are selectively attached to air bubbles and rise to the surface, forming a froth that is collected.

ii. Chemical Reduction: Transforming Compounds into Pure Metals

Chemical reduction techniques are employed to extract metals from their compounds, typically oxides or sulfides. These techniques involve the use of reducing agents, such as carbon monoxide, hydrogen, or aluminum, to remove oxygen from the metal-containing compound, releasing the pure metal.

iii. Refining: Polishing the Metallic Gem

After initial extraction, metals often undergo refining processes to remove impurities and enhance their purity. Refining techniques include:

Electrolysis: Pure metal is deposited onto the cathode of an electrolytic cell, while impurities remain in the electrolyte solution.

Zone refining: A molten zone is moved along a bar of impure metal, causing impurities to concentrate at one end, leaving the purified metal at the other.

Gangue Minerals: The Unsung Heroes of Ore Processing

Gangue minerals, the non-metallic constituents of ores, play a crucial role in the extraction process. These minerals provide the matrix that holds the metal-bearing minerals together and facilitate their processing. However, gangue minerals must be separated from the valuable metals during extraction.

iv. The Significance of Metal Extraction: Shaping Our World

Metal extraction is an essential process that supports various industries and modern technologies:

Construction: Metals are the backbone of infrastructure, from buildings and bridges to vehicles and machinery.

Electronics: Metals like copper, gold, and silver are indispensable components of electronic devices, enabling communication and innovation.

Energy production: Metals play a critical role in energy production, from power generation to renewable energy technologies.

v. Environmental Considerations: Striking a Balance

Metal extraction processes can have environmental impacts, including water pollution, air emissions, and solid waste generation. Sustainable practices are being implemented to minimize these impacts, such as:

Wastewater treatment: Treating wastewater generated during processing to remove pollutants before discharge.

Flue gas treatment: Capturing and treating emissions from furnaces used in metal extraction.

Recycling: Recycling metals reduces the need for primary extraction and minimizes environmental impact.

Metal extraction, the process of unlocking valuable metals from their natural sources, stands as a testament to human ingenuity and the power of chemistry. Understanding the principles of physical separation, chemical reduction, and refining, the role of gangue minerals, and the significance of metal extraction in shaping our world empowers us to appreciate the intricacies of this crucial process and the importance of sustainable practices in minimizing its environmental impact.